When establishing a business relationship with a Chinese supplier, I know the decision can be crucial to the success of my business. Not only can it provide access to high-quality products at competitive prices, but choosing the right supplier also means building a long-lasting, reliable partnership. Here’s my personal guide on what I consider and compare when selecting the best supplier to meet my business needs.

1. Assessing Product Quality

First and foremost, I prioritize product quality. Here’s how I approach it:

- Request Samples: Before placing any bulk orders, I always request samples to test the quality, durability, and functionality. Sampling is an important step in setting a quality standard for future orders.

- Verify Certifications: I make sure that the supplier’s products meet international quality standards (such as CE, RoHS, or ISO) and any specific certifications required in my market.

2. Verifying Supplier Credibility and Ownership of Facilities

One key factor I consider is whether the supplier operates their own factory, as this often indicates a higher level of quality control and reliability compared to trading companies. Here’s how I assess this:

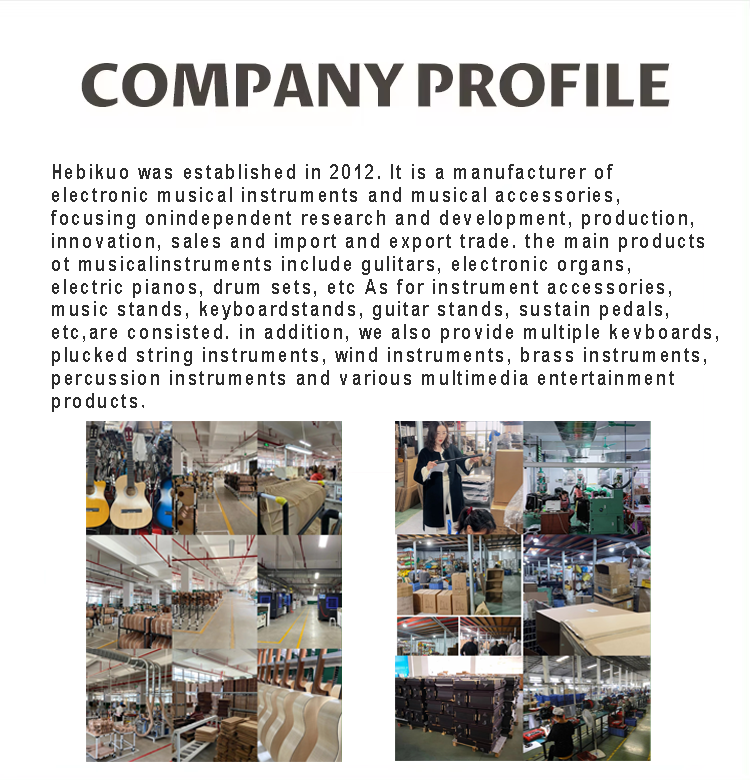

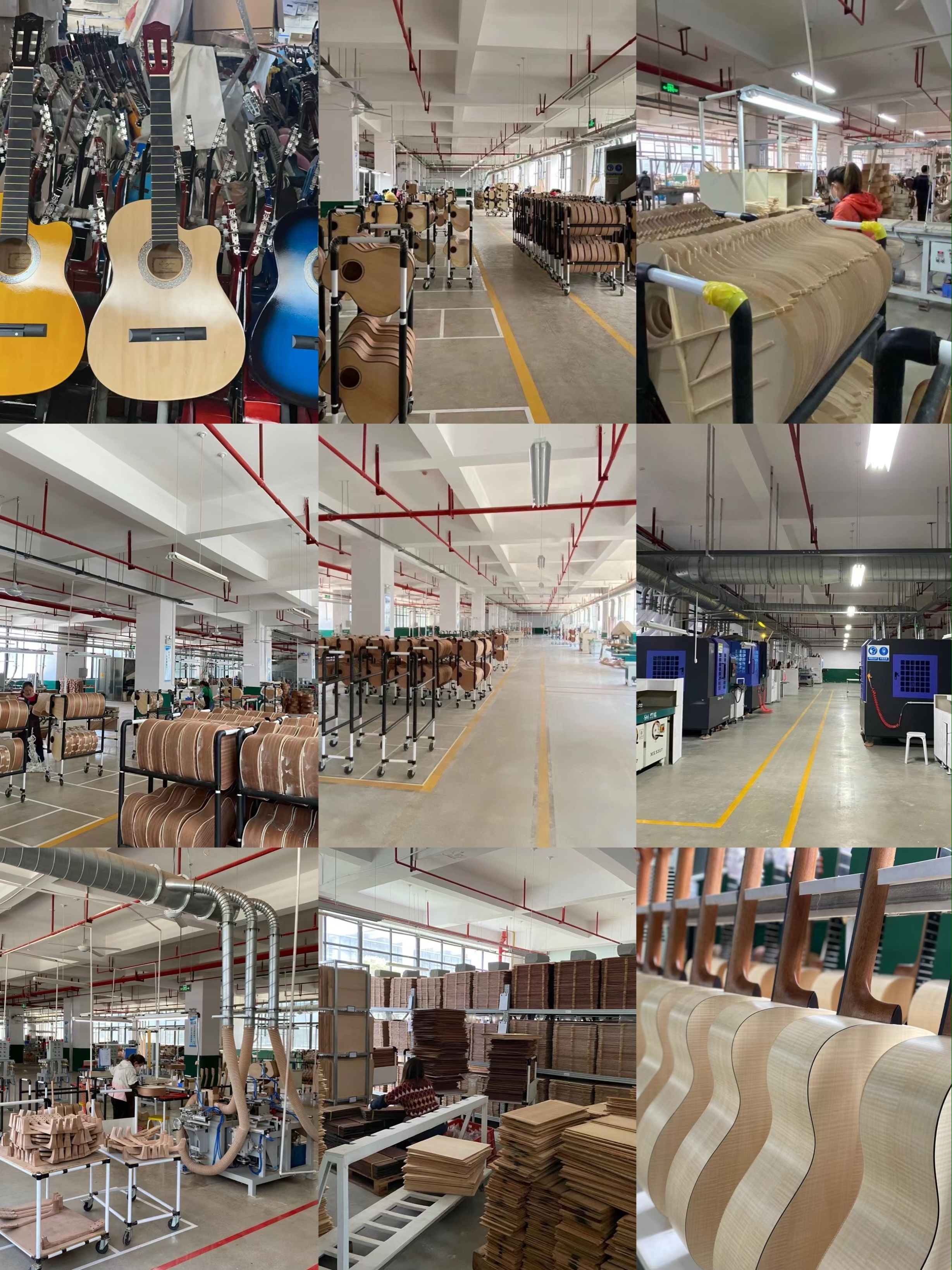

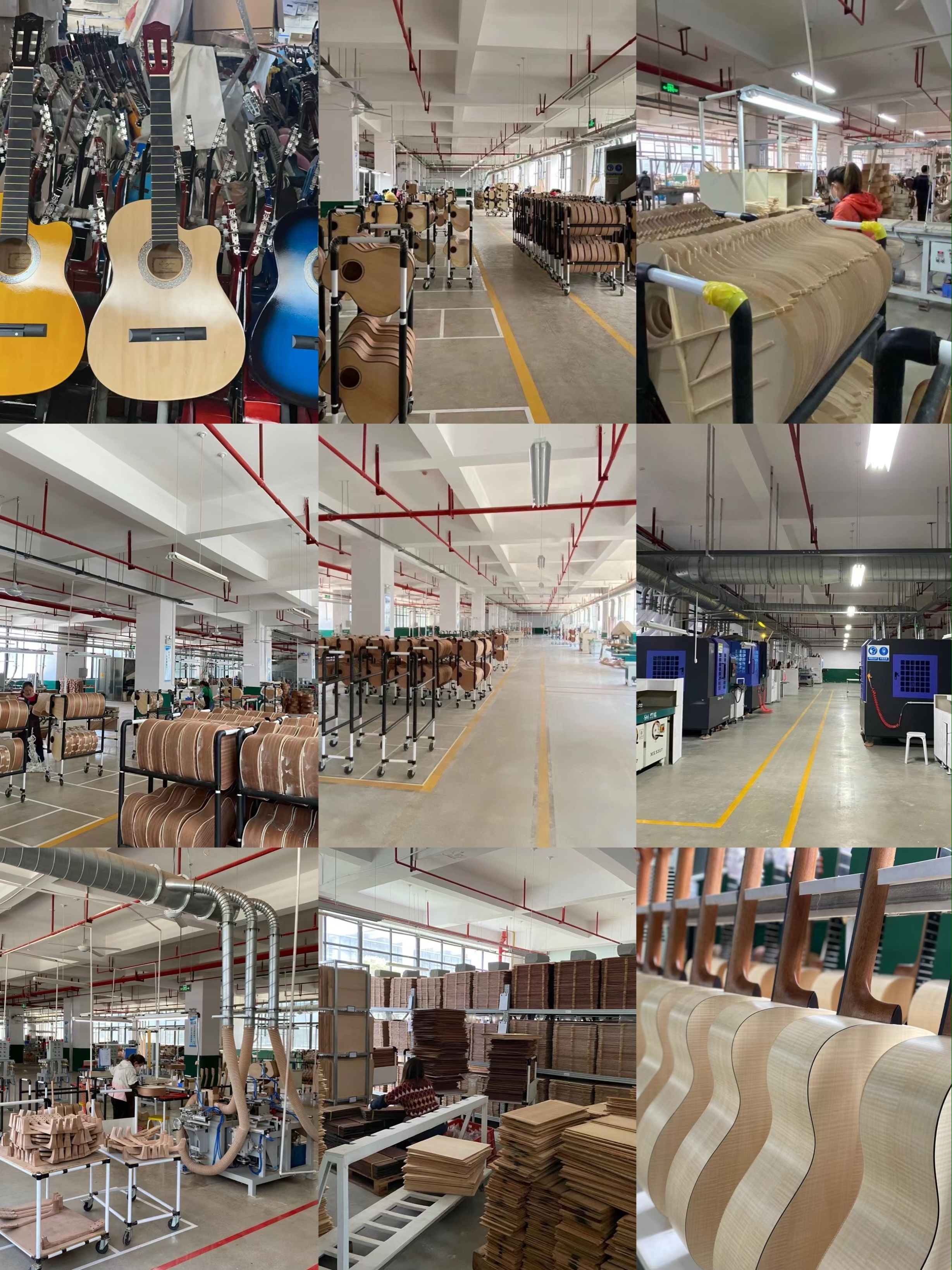

- Distinguish Between Manufacturers and Traders: Many suppliers in China act as trading companies without owning a factory. They source from various manufacturers, which can lead to inconsistencies in quality and pricing. With Hebikuo musical instrument company, I know they have their own factory and warehouse, which helps ensure a more reliable production process.

- Research and Confirm: I look up contact details, credentials, and qualifications on Hebikuo’s website or platforms like Alibaba. This step confirms their credibility and verifies their physical presence as a manufacturer

- Factory Visit or Video Tour: If possible, I arrange an on-site visit. If that’s not feasible, I ask for a video call tour of their facility. This option provides reassurance that their factory is legitimate and that they have experience and capability in producing quality musical instruments.

- Consider Factory Audits: If feasible, I arrange for a factory audit or use a third-party inspection service to confirm their production standards and quality control processes.

3. Balancing Price with Quality

While pricing is an important factor, I know that balancing cost with quality is essential. Here’s my approach:

- Compare Unit Prices: I compare prices among suppliers and keep in mind that extremely low prices may be a red flag for compromised quality.

- Review Payment Terms: Understanding each supplier’s payment terms—such as deposit requirements and accepted payment methods—helps me manage financial risk. Standard terms often involve a deposit upfront, with the balance paid before shipment.

4. Considering Minimum Order Quantities (MOQs)

MOQ requirements can impact my budget and flexibility. Here’s what I look for:

- Evaluate MOQs: Each supplier has different MOQ requirements. I select suppliers whose MOQs align with my budget and sales expectations.

- Negotiate Flexibility: Some suppliers may be open to adjusting their MOQ, especially if there’s potential for a long-term relationship, which can help me test new products more affordably.

5. Checking Production Capacity and Lead Times

The supplier’s production capacity and lead time affect my ability to meet demand consistently. Here’s how I evaluate these aspects:

- Assess Lead Times: I ask about production timeframes for different order quantities and ensure these align with my business schedule.

- Consider Scalability: I choose suppliers with sufficient production capacity to accommodate growth as my business expands. This ensures they can handle increased orders without sacrificing quality or delivery speed.

6. Reviewing Shipping Options

Shipping costs and delivery times are critical to my overall costs and customer satisfaction. Here’s what I consider:

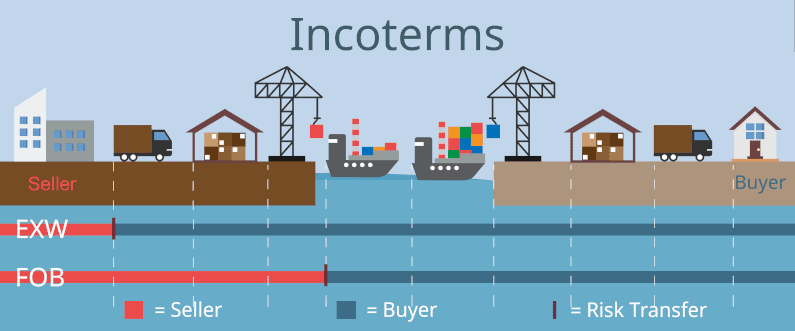

- Compare Shipping Methods and Costs: I discuss available shipping options, estimated delivery times, and costs with each supplier. Sometimes, bulk discounts or managed logistics can be negotiated.

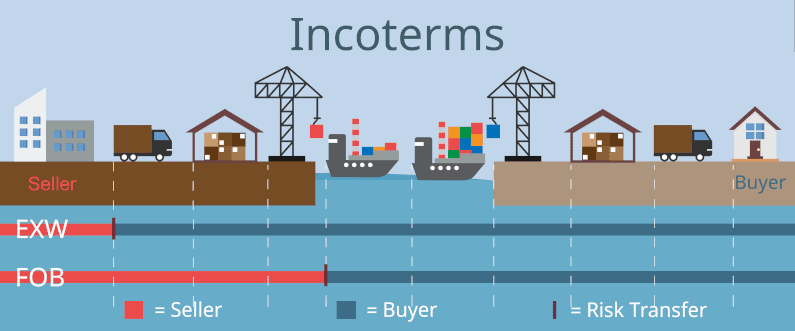

- Clarify Incoterms: I review the delivery terms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), to know which costs and risks are covered by the supplier versus those I’ll need to manage.

7. Prioritizing Communication

Clear communication is the backbone of a successful supplier relationship. Here’s what I focus on:

- Evaluate Responsiveness: I note how quickly and clearly each supplier responds to my inquiries, which reflects their reliability and interest in a strong partnership.

- Language Proficiency: Communication in English (or another shared language) helps me avoid misunderstandings, so I seek suppliers with strong language skills to make processes smoother.

8. Reviewing Reputation and Customer Feedback

To understand the supplier’s credibility and reliability, I look into their reputation through these methods:

- Read Customer Reviews: I go through testimonials and case studies to learn about other clients’ experiences. Many suppliers are also willing to share references upon request.

- Consider Business Longevity: Suppliers with a longer history often have stable, dependable operations and quality assurance processes.

9. Confirming Quality Control Procedures

A solid quality control system is crucial to maintaining consistency. Here’s what I check:

- Ask About Inspections: I discuss their quality inspection process during production and on finished goods. Reputable suppliers often support third-party inspections, which is a reassuring sign.

- Review Return Policies: A clear return or warranty policy shows the supplier’s commitment to quality. I clarify whether they’re willing to replace or refund any defective products, if necessary.

10. Ensuring Intellectual Property (IP) Protection

When it comes to custom products or branding, I take extra steps to protect my IP:

- Draft a Written Agreement: I negotiate contracts that include penalties for any IP violations or unauthorized reproductions.

- Include IP Clauses: I make sure the agreement clearly states my ownership of any custom designs or branding, which minimizes the risk of duplication.

11. Checking for Ethical and Sustainability Standards

If sustainability is a priority, I want to know my supplier values ethical and sustainable practices as much as I do:

- Review Compliance: I ask for details on their ethical practices, including labor standards, environmental policies, and working conditions.

- Request Certifications: Many suppliers can provide certifications (such as FSC for sustainable sourcing), which helps me align my business with responsible sourcing values.

Making the Final Decision

After gathering this information, here’s my process to make the best choice:

- Create a Comparison Chart: I use a scoring system to objectively rank suppliers based on the factors that are most important to me, such as quality, scalability, and communication.

- Prioritize Key Factors: I weigh factors that are non-negotiable for my business. For instance, if consistent quality or fast lead times are essential, I’ll prioritize these over other criteria.

- Consider a Site Visit: When feasible, I arrange a visit to top suppliers or use a third-party inspection service. Seeing their facilities firsthand or through an inspector’s report gives me valuable insight into their operations.

Choosing the right Chinese supplier requires thorough evaluation, but this detailed approach has helped me build reliable, long-term partnerships that support my business goals. With the right supplier, I can access high-quality products at competitive prices, ensuring consistent growth and customer satisfaction.

About hebikuo: